Conductive Elastomers

Electrically conductive elastomers cover an important area in the field of EMC shielding when an additional environmental shielding is required.

They consist of an elastomeric binder (silicone or fluoro-silicone), which is supplied with different fillers depending on the desired shielding performance and contacted materials (prevention of corrosion). We are happy to advise you on the selection!

Electrically conductive elastomers are produced in sheets, as moulded or extruded sections and can also be printed onto surfaces.

Depending on the application and the required profile, o-rings can be supplied as moulded parts or vulcanized from extruded profiles.

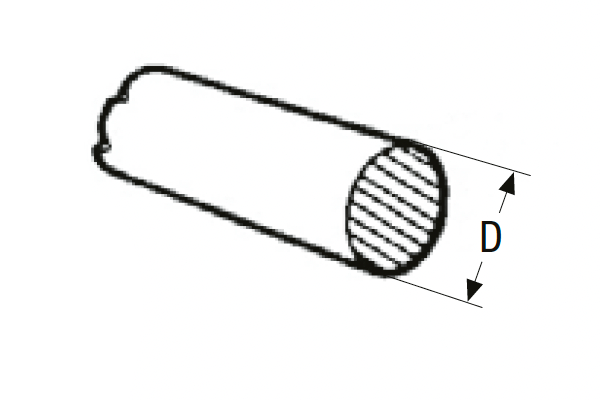

Extruded round profiles can be produced with very small diameters and are therefore well suited for narrow-walled housings.

| Galvanic compatibility | Housing material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

● Good Material code Filler type | Aluminium alloys | Magnesium |

Stainless | Copper | Cadmium | Tin | Nickel | Chromium | Silver | Galvanised Steel |

Titanium | |

A | Silver/Nickel | X | X | ● | ● | X | ■ | ● | ● | ● | X | ● |

B | Silver/Copper | X | X | ● | ● | X | X | ■ | ● | ● | X | ● |

D | Silver/Aluminium | ■ | ■ | ● | ● | ■ | ■ | ■ | ● | ● | ■ | ● |

K | Inert Aluminium (Al Compatible) | ● | ■ | ● | ● | ■ | ● | ● | ● | ● | ■ | ● |

I | Silver/Glass | X | X | ● | ● | X | ■ | ● | ● | ● | X | ● |

G | Silver | X | X | ● | ● | X | ■ | ● | ● | ● | X | ● |

J | Silver/Graphite | ■ | ■ | ● | ● | ■ | ● | ● | ● | ● | ■ | ● |

E | Silver/Nickel | ■ | ■ | ● | ● | ■ | ● | ● | ● | ● | ■ | ● |

O Profile

Part-No. | Ø nominal |

5001.XXYY.010 | 1,02 |

5001.XXYY.014 | 1,35 |

5001.XXYY.016 | 1,57 |

5001.XXYY.018 | 1,78 |

5001.XXYY.020 | 2,03 |

5001.XXYY.024 | 2,36 |

5001.XXYY.026 | 2,62 |

5001.XXYY.028 | 2,84 |

5001.XXYY.030 | 3,02 |

5001.XXYY.032 | 3,18 |

5001.XXYY.033 | 3,30 |

5001.XXYY.035 | 3,53 |

5001.XXYY.038 | 3,81 |

5001.XXYY.041 | 4,06 |

5001.XXYY.048 | 4,78 |

5001.XXYY.055 | 5,49 |

5001.XXYY.064 | 6,35 |

XX: Basic material, YY: Filler, see material table Ⓜ

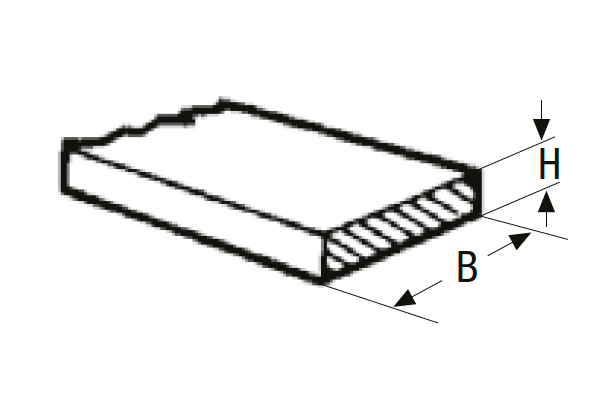

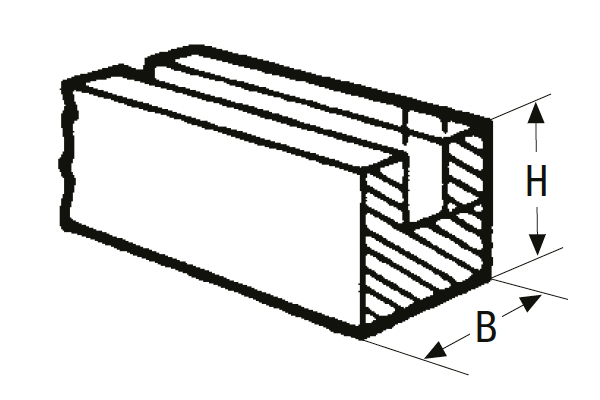

Recctangular Profile

Part-No. | Height | Width |

5004.XXYY.011.016 | 1,07 | 1,60 |

5004.XXYY.016.024 | 1,57 | 2,41 |

5004.XXYY.019.031 | 1,91 | 3,05 |

5004.XXYY.016.032 | 1,57 | 3,18 |

5004.XXYY.016.040 | 1,57 | 3,96 |

5004.XXYY.016.064 | 1,57 | 6,35 |

5004.XXYY.019.127 | 1,91 | 12,70 |

5004.XXYY.032.127 | 3,18 | 12,70 |

5004.XXYY.048.127 | 4,78 | 12,70 |

5004.XXYY.016.191 | 1,57 | 19,05 |

5004.XXYY.016.224 | 1,57 | 22,35 |

XX: Basic material, YY: Filler, see material table Ⓜ

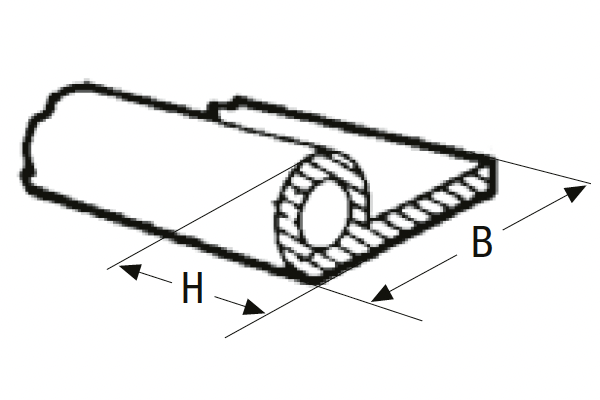

Profile with Fin (P Profile)

Part-No. | Height | Width |

5005.XXYY.051.127 | 5,08 | 12,70 |

5005.XXYY.051.216 | 5,08 | 21,59 |

5005.XXYY.064.127 | 6,35 | 12,70 |

5005.XXYY.064.159 | 6,35 | 15,88 |

5005.XXYY.064.222 | 6,35 | 22,22 |

5005.XXYY.079.222 | 7,92 | 22,22 |

5005.XXYY.091.198 | 9,14 | 19,81 |

XX: Basic material, YY: Filler, see material table Ⓜ

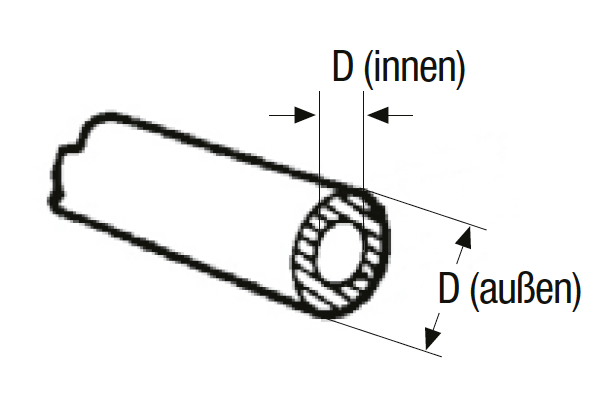

Hollow O Profile

Part-No. | Ø inside | Ø nominal |

5007.XXYY.008.024 | 0,80 | 2,40 |

5007.XXYY.011.032 | 1,14 | 3,18 |

5007.XXYY.013.040 | 1,27 | 3,96 |

5007.XXYY.032.064 | 3,18 | 6,35 |

5007.XXYY.049.079 | 4,88 | 7,92 |

5007.XXYY.064.095 | 6,35 | 9,53 |

XX: Basic material, YY: Filler, see material table Ⓜ

U-Profile

Part-No. | Height | Width |

5009.XXYY.025.025 | 2,54 | 2,54 |

5009.XXYY.028.032 | 2,79 | 3,20 |

5009.XXYY.057.032 | 5,72 | 3,20 |

5009.XXYY.040.040 | 3,94 | 3,96 |

5009.XXYY.040.045 | 3,96 | 4,45 |

5009.XXYY.059.083 | 5,94 | 8,31 |

XX: Basic material, YY: Filler, see material table Ⓜ

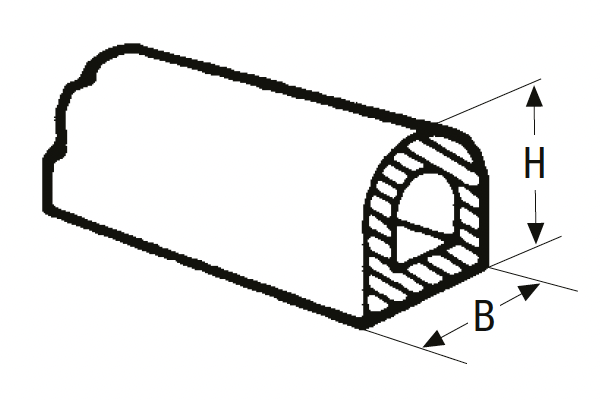

Hollow D Profile

Part-No. | Height | Width |

5008.XXYY.040.040 | 3,96 | 3,96 |

5008.XXYY.047.048 | 4,72 | 4,75 |

5008.XXYY.079.079 | 7,92 | 7,92 |

5008.XXYY.079.079 | 7,92 | 7,92 |

5008.XXYY.082.124 | 8,23 | 12,37 |

5008.XXYY.064.064 | 6,35 | 6,35 |

XX: Basic material, YY: Filler, see material table Ⓜ

Solid D Profile

Part-No. | Height | Width |

5003.XXYY016.014 | 1,63 | 1,40 |

5003.XXYY.017.016 | 1,73 | 1,57 |

5003.XXYY.020.024 | 1,98 | 2,39 |

5003.XXYY.023.020 | 2,26 | 1,98 |

5003.XXYY.025.016 | 2,54 | 1,57 |

5003.XXYY.028.038 | 2,79 | 3,81 |

5003.XXYY.040.030 | 3,96 | 3,00 |

5003.XXYY.045.045 | 4,45 | 4,52 |

5003.XXYY.040.040 | 3,96 | 3,96 |

XX: Basic material, YY: Filler, see material table Ⓜ

Material

Basic material (XX) | Filler (YY) | |

37 - Silicone | 43 | Ag/Ni (1A/1) |

38 - Fluorosilicone | 44 | Ag/Cu 1 (1B/1) |

| 45 | Ag/Cu 2 (1B/2) |

| 46 | Ag/Al 1 (1D/1) |

| 47 | Ag/Al 2 (1D/2) |

| 48 | Ag/Glass 1 (1I/1) |

| 49 | Ag/Glass 3 (1I/3) |

| 50 | Ag/Glass 4 (1I/4) |

| 51 | Ni/Gr 2 (1J/2) |

| 52 | Ni/Gr 3 (1J/3) |

| 53 | Carbon (1F) |

| 54** | Ni/Gr (1J/8) |

| 55* | Ag/Cu (2B) |

| 56* | Ag/Al (2D) |

| 57* | Ni/Gr (2J) |

| 58* | Ag/Cu (2A)) |

Material specification, see page 31

*Only in combination with fluorosilicone

** Flame retardant according to UL94-V0

General Description | |||||||||

EcE Material Reference (Type) | 1A/1 | 1B/1 | 1B/2 | 1D/1 | 1I/1 | 1I/3 | 1I/4 | ||

| nicht ent- flammbar | |||||||||

Elastomer -Typ (Sil - Silikon, F/Sil - Fluorsilikon) | Sil | Sil | Sil | Sil | Sil | Sil | Sil | ||

Füllmaterial (Silber auf Aluminium, Nickel, Kupfer, Glas und Nickel/Graphit) | Ag/Ni | Ag/Cu | Ag/Cu | Ag/Al | Ag/Glas | Ag/Glas | Ag/Glas | ||

Farbe | braun | braun | braun | braun | braun | braun | braun | ||

Electrical Properties | Tol | Test Method |

| ||||||

Spezifischer Durchgangswiderstand (ohm · cm) (wie geliefert) | Max |

|

0,047 |

0,005 |

0,008 |

0,008 |

0,050 |

0,005 | 0,050 - 0,100 |

Schirmwirkung (dB) 200 KHz (magnetisches Feld) |

|

MIL-G-83528 MIL 285 |

70 |

70 |

70 |

70 |

50 |

55 |

55 |

100 MHz (elektrisches Feld) |

| 105 | 115 | 115 | 110 | 65 | 95 | 95 | |

500 MHz (elektrisches Feld) |

| 105 | 115 | 115 | 105 | 70 | 95 | 90 | |

2 GHz (ebene Welle) |

| 100 | 115 | 115 | 100 | 70 | 95 | 90 | |

10 GHz (ebene Welle) |

| 100 | 115 | 115 | 100 | 65 | 95 | 90 | |

Physical Properties | |||||||||

Spezifisches Gewicht (g/cm³) | ±5% | ASTM D-792 | 4,32 | 3,32 | 3,02 | 2,11 | 1,85 | 1,80 | 1,75 |

Härte (Shore A) | ± 5 | ASTM D-2240 | 65 | 75 | 61 | 70 | 65 | 65 | 60 |

Reißfestigkeit (MPa) | Min | ASTM D-412 | 1.25 | 1.25 | 1.00 | 0.90 | 0.55 | 0.35 | 0.90 |

Dehnung (%) | Min | ASTM D-412 | 100 | 100 | 100 | 100 | 60 | 75 | 80 |

Druckverformungsrest (%) | Max | ASTM D-395 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Obere Betriebstemperatur (°C) | – |

| 160 | 125 | 125 | 160 | 160 | 160 | 160 |

Untere Betriebstemperatur (°C) | – | ASTM D-1329 | -50 | -50 | -50 | -50 | -50 | -50 | -50 |

General Description | ||||||||||

EcE Material Reference (Type) | 1J/2 | 1J/3 | 1J/8 | 1D/2 | 2A | 2B | 2D | 2J | ||

|

|

| nicht entflammbar |

|

|

|

|

| ||

Elastomer -Typ (Sil - Silikon, F/Sil - Fluorsilikon) | Sil | Sil | Sil | Sil | F/Sil | F/Sil | F/Sil | F/Sil | ||

Füllmaterial (Silber auf Aluminium, Nickel, Kupfer, Glas und Nickel/Graphit) | Ni/Gr | Ni/Gr | Ni/Gr | Ag/Al | Ag/Ni | Ag/Cu | Ag/Al | Ni/Gr | ||

Farbe | grau | grau | grau | braun | braun | braun | h.-grün | d.-grün | ||

Electrical Properties | Tol | Test Method |

| |||||||

Spezifischer Durchgangswiderstand (ohm · cm) (wie geliefert) | Max |

|

0,050 | 0,100- 0,500 | 0,050 0,100 |

0,008 |

0,005 |

0,005 |

0,010 |

0,050 |

Schirmwirkung (dB) 200 KHz (magnetisches Feld) |

|

MIL-G-83528 MIL 285 |

70 |

70 |

70 |

70 |

75 |

75 |

70 |

70 |

100 MHz (elektrisches Feld) |

| 95 | 95 | 95 | 100 | 110 | 110 | 110 | 100 | |

500 MHz (elektrisches Feld) |

| 90 | 90 | 90 | 100 | 110 | 120 | 105 | 100 | |

2 GHz (ebene Welle) |

| 90 | 90 | 90 | 100 | 105 | 120 | 100 | 100 | |

10 GHz (ebene Welle) |

| 90 | 90 | 90 | 100 | 100 | 120 | 100 | 100 | |

Physical Properties | ||||||||||

Spezifisches Gewicht (g/cm³) | ±5% | ASTM D-792 | 2,45 | 1,99 | 2,30 | 2,00 | 4,60 | 5,00 | 2,70 | 3,25 |

Härte (Shore A) | ± 5 | ASTM D-2240 | 80 | 60 | 75 | 65 | 80 | 75 | 70 | 80 |

Reißfestigkeit (MPa) | Min | ASTM D-412 | 2.00 | 1.00 | 1,40 | 0.90 | 1.25 | 1.25 | 0.55 | 0.75 |

Dehnung (%) | Min | ASTM D-412 | 150 | 100 | 125 | 175 | 100 | 100 | 100 | 100 |

Druckverformungsrest (%) | Max | ASTM D-395 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Obere Betriebstemperatur (°C) | – |

| 160 | 160 | 160 | 160 | 160 | 125 | 160 | 160 |

Untere Betriebstemperatur (°C) | – | ASTM D-1329 | -50 | -50 | -50 | -50 | -50 | -55 | -55 | -55 |